Aluminum Applications for Vacuum Chambers and Semiconductors

View Full Size

One area in the aluminum industry that doesn’t get enough attention is vacuum chambers and semiconductors. These technically advanced fields have rigid material specifications and only certain grades are suitable. Aluminum, with its many benefits and high performance, is a perfect choice for such demanding applications.

While these two technologies are distinct from each other in significant ways, there is some overlap, as it is necessary to build and test semiconductors in a vacuum or inert gas environment. Each application has its own material demands and aluminum is used to meet many of them.

Today we’ll be looking at how aluminum alloys are used in vacuum chambers and semiconductors.

What are vacuum chambers?

A vacuum chamber is an enclosed cavity in which all air and other gases have been removed using a vacuum pump. The low-pressure environment inside the chamber makes it possible to carry out scientific experiments and to conduct tests on devices that may need to operate in vacuum-like conditions (including outer space). Other procedures require a gaseous environment produced when gases are introduced into a vacuum chamber after the atmospheric air has been evacuated. There are other mechanical processes that require this equipment, including vacuum drying and coating.

These enclosures are generally made from metals such as aluminum, stainless steel, brass, or other materials, including ceramic, glass and acrylic. These materials also provide varying degrees of protection from external magnetic fields based on their thickness, resistivity and permeability. Aluminum is a popular choice for vacuum chambers because of its high strength-to-weight ratio and other benefits.

When constructing a vacuum chamber, it will need multiple ports with vacuum flanges for instruments to access the chamber. These ports will be sealed depending on technical requirements. In low-vacuum applications, elastomer o-rings might be used. In high-vacuum applications, the flanges will have knife edges machined onto them, which will then cut into a metal gasket as the flange is bolted on.

Why is aluminum a good choice for vacuum chambers?

Aluminum makes an excellent option for vacuum chambers because of its many benefits. First, thanks to of its tremendous strength, it can withstand the high pressure and stressors it will be placed under by a vacuum chamber. Its superior corrosion resistance makes it optimal for use scenarios in which chemicals or environmental exposure could impact the longevity of an application.

There are also special factors that apply specifically to vacuum chambers. Aluminum has seven orders of magnitude less hydrogen permeation compared to stainless steel. This means that an aluminum vacuum chamber has less chance of being contaminated by hydrogen gas, water or hydrocarbon vapor. Aluminum also allows for less carbon contamination when compared to other metals such as stainless steel. As with hydrogen, this results in more protection from carbon gas contamination in the vacuum.

Another benefit of working with aluminum alloys is the thin aluminum oxide coating that naturally forms on aluminum offers a barrier that reduces the diffusion of contaminants, including hydrogen, oxygen and carbon. Other benefits include the ease of anodization, high vibration dampening, lower residual radiation and other benefits we haven’t mentioned yet, such as increased machinability and formability, that make aluminum easy to work with.

What is a semiconductor?

A semiconductor device is an electronic component that uses electrical conduction but has traits that are in between that of a conductor, for instance copper, and that of an insulator, such as glass. These devices use electrical conduction in the solid state as opposed to in the gaseous state or thermionic emission in a vacuum, and they have replaced vacuum tubes in most modern applications.

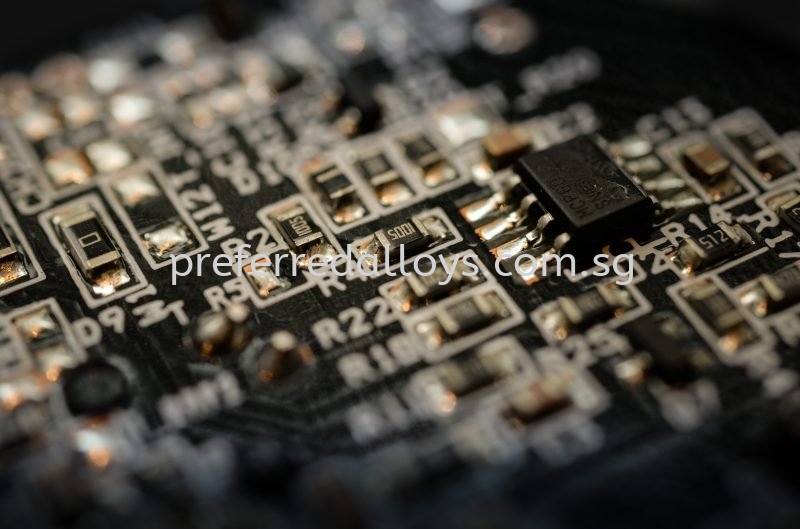

The most common use of semiconductors is in integrated circuit chips. Our modern computing devices, including mobile phones and tablets, might contain billions of tiny semiconductors joined on single chips all interconnected on a single semiconductor wafer.

The conductivity of a semiconductor can be manipulated in several ways, such as by introducing an electric or magnetic field, by exposing it to light or heat, or due to the mechanical deformation of a doped monocrystalline silicon grid. While the technical explanation is quite detailed, the manipulation of semiconductors is what has made our current digital revolution possible.

How is aluminum used in semiconductors?

Aluminum has many properties that make it a primary choice for use in semiconductors and microchips. For instance, aluminum has superior adhesion to silicon dioxide, a major component of semiconductors (this is where Silicon Valley got its name). It’s electrical properties, namely that it has low electrical resistance and makes for excellent contacting with wire bonds, are another benefit of aluminum. Also important is that it’s easy to structure aluminum in dry etch processes, a crucial step in making semiconductors. While other metals, like copper and silver, offer better corrosion resistance and electrical toughness, they are also much more expensive than aluminum.

One of the most prevalent applications for aluminum in the manufacture of semiconductors is in the process of sputtering technology. The thin layering of nano thicknesses of high-purity metals and silicon in microprocessor wafers is accomplished through a process of physical vapor deposition known as sputtering. Material is ejected from a target and deposited on a substrate layer of silicon in a vacuum chamber that has been filled with gas to help facilitate the procedure; usually an inert gas such as argon.

The backing plates for these targets are made of aluminum with the high purity materials for deposition, such as tantalum, copper, titanium, tungsten or 99.9999% pure aluminum, bonded to their surface. Photoelectric or chemical etching of the substrate’s conductive surface creates the microscopic circuitry patterns used in the semiconductor’s function.

The most common aluminum alloy in semiconductor processing is 6061. To ensure the best performance of the alloy, generally a protective anodized layer will be applied to the surface of the metal, which will boost the corrosion resistance.

Because they are such precise devices, corrosion and other problems must be monitored closely. Several factors have been found to contribute to corrosion in semiconductor devices, for instance packaging them in plastic.

Your Technical Services Professional

At Preferred Alloys, we understand that our clients have the highest expectations for the performance of the materials they use in their applications. We are committed to providing only the best, most reliable metals to your exact specifications. Thanks to the experience and dedication of our team, we’re able to help at every step of the procurement process.

Contact us today to learn more about our affordable and convenient aluminum products.

While these two technologies are distinct from each other in significant ways, there is some overlap, as it is necessary to build and test semiconductors in a vacuum or inert gas environment. Each application has its own material demands and aluminum is used to meet many of them.

Today we’ll be looking at how aluminum alloys are used in vacuum chambers and semiconductors.

What are vacuum chambers?

A vacuum chamber is an enclosed cavity in which all air and other gases have been removed using a vacuum pump. The low-pressure environment inside the chamber makes it possible to carry out scientific experiments and to conduct tests on devices that may need to operate in vacuum-like conditions (including outer space). Other procedures require a gaseous environment produced when gases are introduced into a vacuum chamber after the atmospheric air has been evacuated. There are other mechanical processes that require this equipment, including vacuum drying and coating.

These enclosures are generally made from metals such as aluminum, stainless steel, brass, or other materials, including ceramic, glass and acrylic. These materials also provide varying degrees of protection from external magnetic fields based on their thickness, resistivity and permeability. Aluminum is a popular choice for vacuum chambers because of its high strength-to-weight ratio and other benefits.

When constructing a vacuum chamber, it will need multiple ports with vacuum flanges for instruments to access the chamber. These ports will be sealed depending on technical requirements. In low-vacuum applications, elastomer o-rings might be used. In high-vacuum applications, the flanges will have knife edges machined onto them, which will then cut into a metal gasket as the flange is bolted on.

Why is aluminum a good choice for vacuum chambers?

Aluminum makes an excellent option for vacuum chambers because of its many benefits. First, thanks to of its tremendous strength, it can withstand the high pressure and stressors it will be placed under by a vacuum chamber. Its superior corrosion resistance makes it optimal for use scenarios in which chemicals or environmental exposure could impact the longevity of an application.

There are also special factors that apply specifically to vacuum chambers. Aluminum has seven orders of magnitude less hydrogen permeation compared to stainless steel. This means that an aluminum vacuum chamber has less chance of being contaminated by hydrogen gas, water or hydrocarbon vapor. Aluminum also allows for less carbon contamination when compared to other metals such as stainless steel. As with hydrogen, this results in more protection from carbon gas contamination in the vacuum.

Another benefit of working with aluminum alloys is the thin aluminum oxide coating that naturally forms on aluminum offers a barrier that reduces the diffusion of contaminants, including hydrogen, oxygen and carbon. Other benefits include the ease of anodization, high vibration dampening, lower residual radiation and other benefits we haven’t mentioned yet, such as increased machinability and formability, that make aluminum easy to work with.

What is a semiconductor?

A semiconductor device is an electronic component that uses electrical conduction but has traits that are in between that of a conductor, for instance copper, and that of an insulator, such as glass. These devices use electrical conduction in the solid state as opposed to in the gaseous state or thermionic emission in a vacuum, and they have replaced vacuum tubes in most modern applications.

The most common use of semiconductors is in integrated circuit chips. Our modern computing devices, including mobile phones and tablets, might contain billions of tiny semiconductors joined on single chips all interconnected on a single semiconductor wafer.

The conductivity of a semiconductor can be manipulated in several ways, such as by introducing an electric or magnetic field, by exposing it to light or heat, or due to the mechanical deformation of a doped monocrystalline silicon grid. While the technical explanation is quite detailed, the manipulation of semiconductors is what has made our current digital revolution possible.

How is aluminum used in semiconductors?

Aluminum has many properties that make it a primary choice for use in semiconductors and microchips. For instance, aluminum has superior adhesion to silicon dioxide, a major component of semiconductors (this is where Silicon Valley got its name). It’s electrical properties, namely that it has low electrical resistance and makes for excellent contacting with wire bonds, are another benefit of aluminum. Also important is that it’s easy to structure aluminum in dry etch processes, a crucial step in making semiconductors. While other metals, like copper and silver, offer better corrosion resistance and electrical toughness, they are also much more expensive than aluminum.

One of the most prevalent applications for aluminum in the manufacture of semiconductors is in the process of sputtering technology. The thin layering of nano thicknesses of high-purity metals and silicon in microprocessor wafers is accomplished through a process of physical vapor deposition known as sputtering. Material is ejected from a target and deposited on a substrate layer of silicon in a vacuum chamber that has been filled with gas to help facilitate the procedure; usually an inert gas such as argon.

The backing plates for these targets are made of aluminum with the high purity materials for deposition, such as tantalum, copper, titanium, tungsten or 99.9999% pure aluminum, bonded to their surface. Photoelectric or chemical etching of the substrate’s conductive surface creates the microscopic circuitry patterns used in the semiconductor’s function.

The most common aluminum alloy in semiconductor processing is 6061. To ensure the best performance of the alloy, generally a protective anodized layer will be applied to the surface of the metal, which will boost the corrosion resistance.

Because they are such precise devices, corrosion and other problems must be monitored closely. Several factors have been found to contribute to corrosion in semiconductor devices, for instance packaging them in plastic.

Your Technical Services Professional

At Preferred Alloys, we understand that our clients have the highest expectations for the performance of the materials they use in their applications. We are committed to providing only the best, most reliable metals to your exact specifications. Thanks to the experience and dedication of our team, we’re able to help at every step of the procurement process.

Contact us today to learn more about our affordable and convenient aluminum products.

.png)